Zero-Turn Laser Grading

Precise laser finish grading

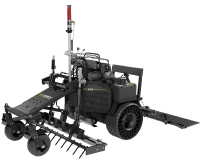

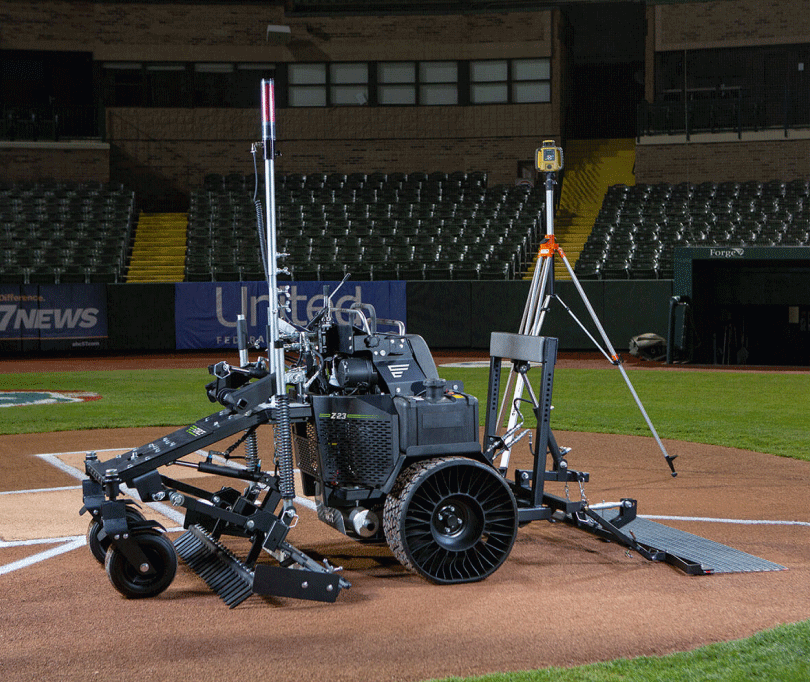

The Z-23 is the world’s first and only stand-on zero-turn laser grading machine, with accuracy plus-or-minus an eighth of an inch! (0.125 inch, 3.175mm) This patented, fully automatic laser grading system delivers unprecedented affordability and finish-grade accuracy to the sports turf and flatwork industries. The Z-23 has a dramatically smaller and lighter footprint than other laser grading machines, enabling laser finish-grading in tight areas and on materials where over compaction of the soil is unacceptable.

Overview

World-class results for every field

Everything You Need

- Light Footprint - With a dramatically smaller and lighter footprint than other laser grading machines, the Z-23 enables laser finish-grading in tight areas and on materials where over compaction of the soil is unacceptable.

- Internal Hydraulic Control System - The laser-ready build configuration can be operated manually without the use of the separately purchased laser electronics.

- All The Bells and Whistles - The Z-23 has a range of laser grading accessories to fit the requirements of your job. This includes a range of transmitters, tripods, grade rods, and other laser system accessories.

Force Advantages

- Accuracy - When every inch matters, the tolerances provided by our RVF technology delivers consistent results.

- Ownership - This compact-platform system empowers contractors to expand service offerings and get more done.

- Visibility - The stand-on zero-turn design allows operators to clearly see the work in progress and respond more quickly to the work site soil conditions.

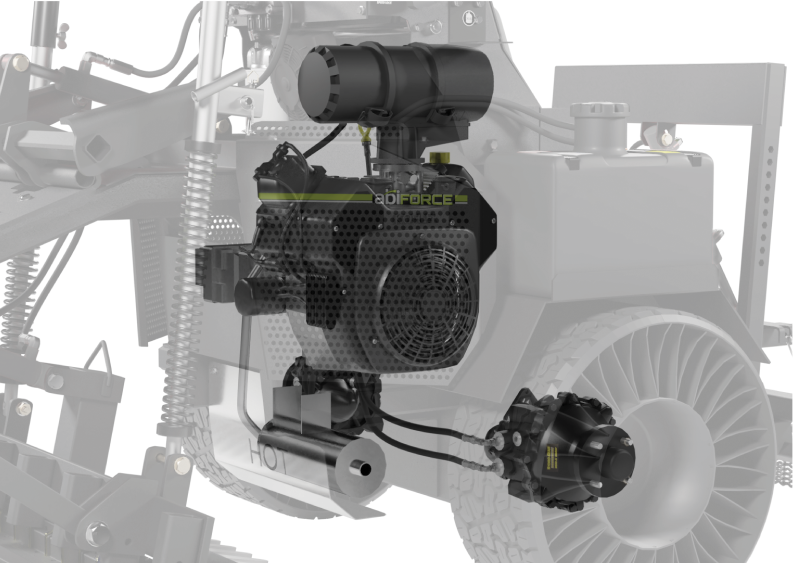

Internal Hydraulic Control System

The hydraulic system on the Z-23 can be built with a manual-operation exclusive or manual/laser-ready configuration. The manual-operation exclusive build is not upgradable after initial factory-build. The laser-ready build configuration can be operated manually without the use of the separately purchased laser electronics should an operator not have them available.

Machine-Side Laser Electronics

The available machine-side laser electronics package transforms the Z-23 into an automated laser grading machine. This system is perfectly matched and pre-programmed for plug-and-play operation.

Transmitter, Tripod, and Accessories

We offer a range of transmitters, tripods, grade rods, and other laser system accessories to suit the requirements for your job. The Z-23 is also able to be paired with almost any flat, single, or dual-slope laser transmitter you may already own.

Attachments

The Ripping Teeth make easy work of extreme hardpan and vegetation outside of the field.

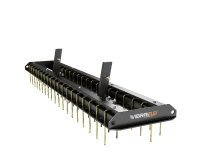

Evenly staggered U-pins transfer vibration and flex from front to back, dancing along the infield to shatter surface tension.

Our proprietary Stealth Blade design offers the perfect subsurface compaction relief.

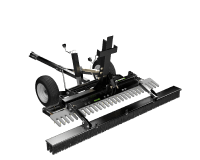

Skip the handwork and quickly level and grade in the tightest areas or on surfaces where a light footprint is necessary.

The scoop can carry up to 300 pounds of mulch or soil and place it right where you want it.

The Fine Finish Broom creates the perfect finish in both high and low moisture conditions on well-maintained surfaces.

Provides a perfect finish for pro-level infield conditioners.

A perfect drag for surfaces with more moisture and also has a built-in leveling bar.

The rear soil finisher attachment will take your soil conditioning and landscape finishing capabilities to a whole new level.

Two staggered rows of 1/4" or 1/8" VibraFlex pins that are designed to remove tire compression and air out the field.

A rigid metal mat with built-in leveling bar is perfect for every-day use and a perfect finish.

Ideal to prepare an infield ready for play with heavy gauge yet flexible rust resistant galvanized steel mesh.

Designed to fracture and loosen material to keep the optional Mini-Box loaded with material.

The underbelly roller has a 58” working width & an 8” roller diameter.

Features

Manufactured, Right Here

You want the best quality materials, you want the highest quality workmanship, you want your attachments made in the United States of America. That’s why, since 1997, we’ve been manufacturing and selling equipment built to exceed your expectations, just like we should.

36-Month, Warranty

We build equipment with commercial-grade construction and superior craftsmanship, so you can rest assured it will last a very long time. And to back that up, we offer a 36-month limited warranty on this product. See warranty documentation for details.

Reviews

In my 40 plus years of working on fields as a player, high school coach, collegiate coach and now maintaining the fields at the Softball Hall of Fame I have never had one piece of equipment that has made as much of an impact of maintaining fields as the ABI Force. The Force is such a versatile and agile piece of equipment that performs a multitude of jobs for us that we never were able to do or it performs these jobs so much better and efficiently for us than in the past. The greatest impact the Force makes on our facility is our ability to laser weekly after each tournament event. We are now able to maintain our surfaces on a weekly basis by managing and replacing our material, preventing low spots in our infield due to heavy play. This provides us with a safer surface that is manageable both in dry and wet conditions. I give the Force my highest recommendation for an infield grooming machine.

The ABI Force from ABI Attachments has been a complete game changer, at the USA Softball Hall of Fame Stadium, here in Oklahoma City, OK. Being able to laser grade our infields whenever we want and how we want has been an absolute blessing! We are now better able to not only control where our water travels from our infields, but we are also better able to control our moisture throughout the days, weeks and months of a softball season. The ability to pitch our fields in different directions almost on command has changed the way we take care of our softball fields.This machine has also saved us time and labor! Being able to operate multiple attachments at the same time makes the work much more efficient and less strenuous on our personnel. We essentially have gained more man power without having to hire more workers. This machine is a BEAST!

With the ABI force I gotta say it’s a one in a kind of machine with it is anyways, but with what it can do it’s priceless for a grounds crew . I have 10 fields I mostly use the ABI force for and with the ABI and myself I can get all 6 fields spiked leveled and groomed all in 4 hours. The district I work for didn’t have a groomer they used a bobcat to do it’s work in the past this is something I pushed for and sold my boss on getting and we did. This has replaced 4 guys. The ABI is a huge time saver for me now I have those four guys mowing other areas in the district and helping.

We have been using our ABI Force Z23 for just over a year now, and it has become an indispensable piece of equipment. From the obvious use on our districts Baseball and Softball field, to maintaining our clay running tracks at the middle schools. We also use it with our grounds team to spot aerate, overseed, and fertilize smaller turf areas with challenges rather than blanket treat all turf areas. This has been saving the district hundreds of dollars twice a year. My athletic groundskeepers at the high school also asked to use it to widen the base paths on our varsity and JV fields to allow a more normal path of travel for the 6 foot wide attachments. Our coach and Athletic Director were thrilled with the results. This never would have happened if it required a sod cutter, tractor bucket, and days of raking to prep the ground. I highly recommend this over any other piece of grooming option!

Specs

| Power | Kohler® Command Pro 25 hp EFI V-Twin OHV (17.2kW) | 747cc | 4-Cycle Air Cooled | Gasoline | Model ECH740 |

| Air Filter | Heavy Duty 2-Stage Cyclonic canister air filtration system |

| Fuel | 6 gallon/22.7125 liter capacity with fuel gauge | Unleaded gasoline |

| Electrical | 20 amp Regulated alternator | 350 CCA at 0 degrees - battery |

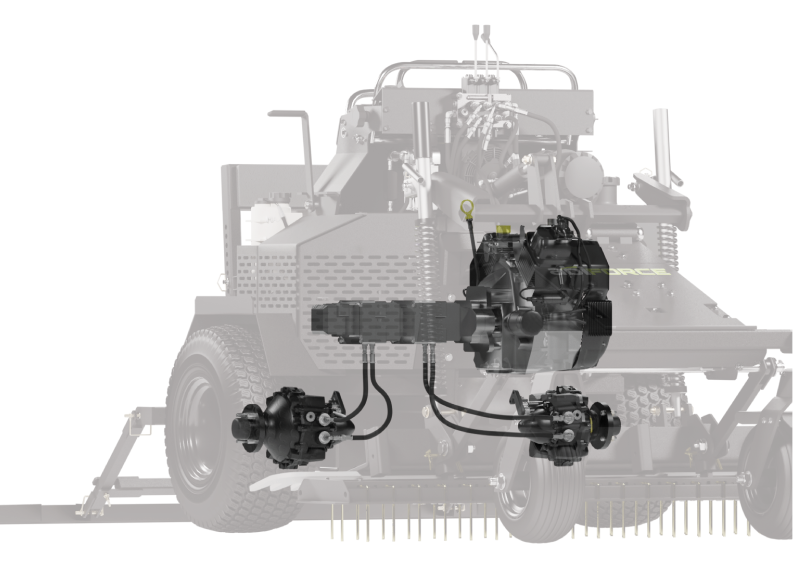

| Drive | Hydrostatic zero-turn | HydroGear variable displacement pumps & fixed displacement wheel motors |

| Speed | Forward 0-10 mph; Reverse 0-4 mph |

| Braking | Dynamic braking via hydrostatic transmission | Integrated parking brake |

| Tires & Wheels | Front (Air): 13 x 6.50-6, Rear: 24 x 12.00-12 (Air or Optional Tweel) |

| Frame Construction | Rugged tube steel |

| Mid-Mount System | Independent hydraulic lift & pitch controls with adjustable & lockable spring-loaded down force with Responsive Variable Force (RVF) technology. |

| Rear-Mount System | Hydraulic lift control with articulation |

| Towing Capacity | 1-1/4" receiver - 2,000 lbs. towing capacity at slow speed on flat and open ground only! Never tow anything on an incline! |

| Operator Experience | Cushioned knee pad & spring cushioned standing platform | Cushioned zero-turn steering levers | Dash indicator lights | USB power port | Cup holder | Machine mount assistance bar |

| Environmental | EPA & CARB compliant |

| Base Unit Weight | 1,300 lbs. |

| Dimensions | 93" L x 56" W x 57"H | 72"-84" With optional rear attachments |

| Limited Warranty | 36-month machine and accessories/36-month unlimited hour commercial warranty (refer to manual) |

Support

- ABI Force Z-23 Owner's Manual

- Finish Blade

- Kohler Command PRO

- Service Schedule

- Broom Assembly

- Mini box assembly

- Edger (Before 6/1/2017)

- VibraFlex Assembly

- Mat & Broom Warranty

- VibraFlex Warranty

- Rear Vibraflex

- Coco Mat

- Fine Finish Broom

- Pro Finisher

- Rigid Dragmat

- Flexible Dragmat

- Rear Cultipacker Instructional Sheet

- Rear Rake Attachment Instructional Sheet

- Electric Spreader Instruction Sheet

- Edger Attachment Instruction Sheet to 4/2021

- Edger Attachment Instruction Sheet after 4/2021

- Finish Blade Kit Instruction Sheet

- Aerator Quick Start Guide

- ABI Force Z-23 Speedometer Installation Guide

- Rear Pivot Lift Instruction Guide

- Warranty

- Infield Groomers Brochure

- Mobile Work Station Kit Installation Guide

- Laser Installation Manual

- AERA-Vator Quick Start Guide